Our strengths

Sanwa's automatic platen cutting and creasing machine has been introduced not only in Japan but also in more than 30 countries around the world. As a result of the in-house production system including the design, parts processing and assembling, we manufacture high-performance and high-quality products. The original design, skill full engineers and the after service are our cores, and with those strengths, we will meet customers’ expectations.

Our Automatic Platen Cutting and Creasing Machines

New development, options, maintenance

We pursue satisfaction improvement in all

Thanks to our original sheet transportation system, we solve post press troubles such as sheet piling at delivery. “Stressless sheet transportation” has been our concept of all time, and based on this concept, we keep improve and developed new machines.

Taking advantage of our know-how of running paperboards and thin papers, we are also challenging on the development of new corrugated machines. At all the segments, customer satisfaction is our motto.

Based on our experiences, and the flexible design skills, we manufacture the products which meet the customer expectations.

By folding the box layout, a sheet turns to a box.

Punching out the box layout from a sheet.

Those boxes are used for the packages for products which are essential to our lives such as foods, cosmetics, medicines and tissues.

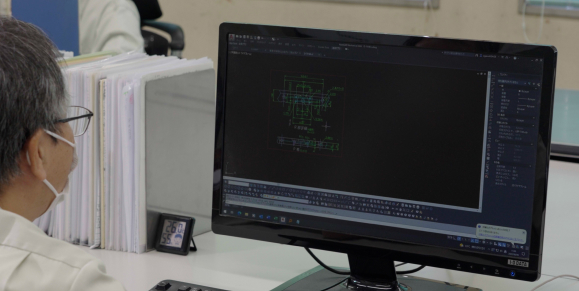

Design

As one team, we answer to customers’ expectation.

Our knowledgeable design team draws and creates original parts and new machines which meet the customers’ expectations.

Our focus is on listening sincerely to our customers’ voice to solve problems and improve the machine performance. The sales department, the skillful engineers and the design department works together as one team, and we propose the best machine to the customer.

In addition, we believe that design, processing, and assembly need to be trinity, so we concentrate all functions at the head office and achieve both cost saving and ensuring the quality.

In addition, Sanwa Manufacturing, which believes that design, processing, and assembly need to be trinity, so we concentrate all functions at the head office to achieve both cost saving and ensuring the quality.

We continue to take the advantage of the latest technologies such as AI and IoT. With those technologies, we create high value machines to the market.

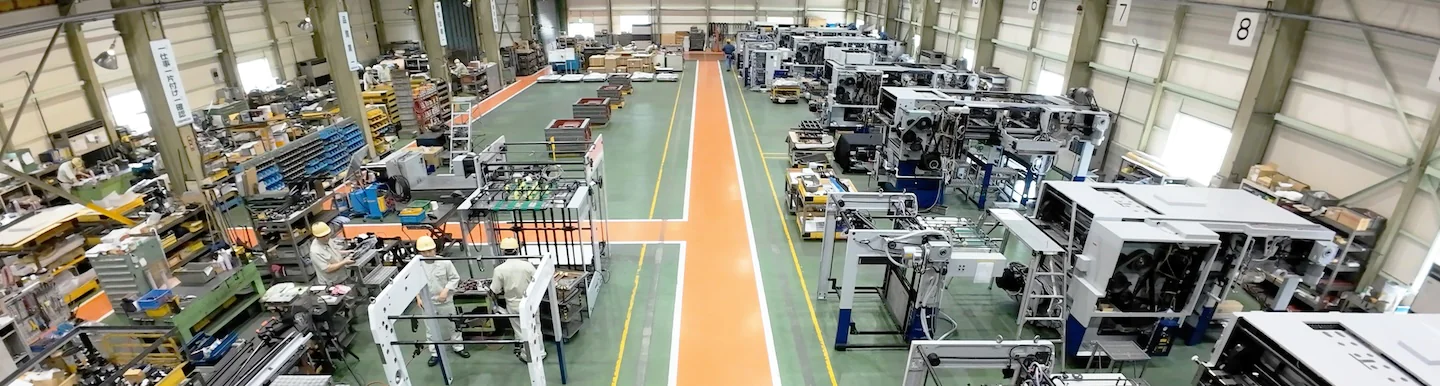

Manufacturing

We conduct the strict quality control and process control to ensure the high quality and high performance.

We manufacture high-quality products through the quality control in all processes, from parts processing to assembly and installation work. By building state-of-the-art production lines and refining our unique production technologies, we are committed to initiatives to reduce delivery times and costs.

The processing plant is equipped with the latest machinery, including large-scale five-face processing machines and machining center. At the assembly plant, experienced engineers assemble machines with high precision and ship the products that have passed the strict Sanwa standards.

We focus on inheriting the skills to the next generations. Moreover, we install new machineries to maximize the skills of our engineers.

Support

We are ready for the quick parts supply.

To ensure the customer’s productivity, we believe the speedy after service is important.

We store the repairing parts in the huge parts shelves at our factory for the quick response.

The fact that sales representatives and the service engineer who is in charge of machine installation and maintenance listens to the voice of the customer and make proposals from the customer's perspective is also a strength of Sanwa Manufacturing, and this is the one of the reasons why there are many customers who have been with us for a long time.